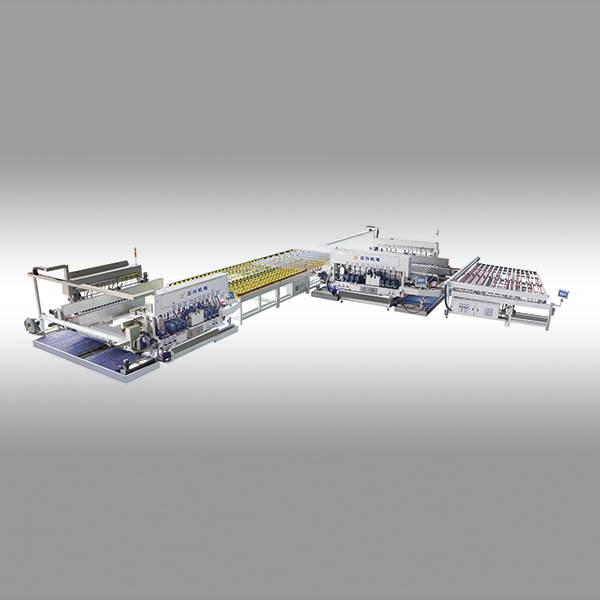

ulayini wokuhlela kabili isivinini esikhulu sengilazi yokuqedela ithebula lokudlulisa

I-FH4225 SM2242GT + ZT4225 + SM2225GTS

Lawula ikhompyutha

Uhlelo oluqondile lokulinganisa i-servo

ububanzi ukulungiswa uhlelo

Izingxenye ezisezingeni eliphakeme ze-elektroniki

Womoya wokucwebezelisa uhlelo

Imoto ka-Arris

Ithebula lokudlulisa ukusebenza kahle okuphezulu

Ithebula lokudlulisa ukusebenza kahle okuphezulu

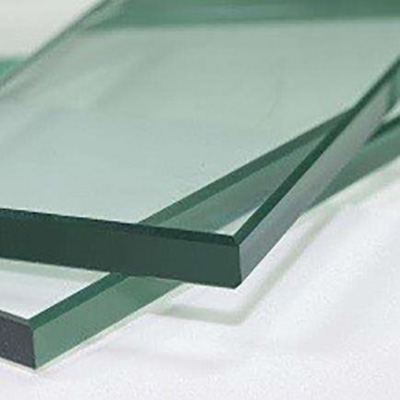

Isingeniso Somshini

Ithebula lokulinganisa ingilazi

Uhlelo lweDrayivu

Le mishini isetshenziselwa ukudlulisa nokubeka ingilazi ezocutshungulwa, yenza isilinganiso esinembile sobude, ububanzi nobukhulu bengilazi, bese idlulisa imininingwane kugrilla onqenqemeni olungabili neminye imishini yokucubungula ukuze kuqhutshekwe kwenziwe ingilazi.

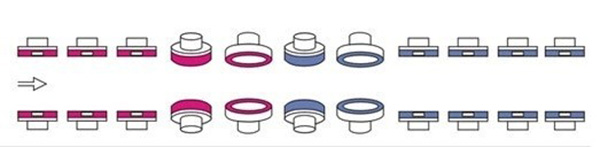

Ukwakhiwa kwetafula lokulinganisa ingilazi kufaka izingxenye ezine njengezingezansi:

1. Ithebula lesikhundla

Ukudluliswa kwengilazi okuya phambili noma ohlangothini kuqhutshwa yisiguquli semvamisa futhi imvamisa eguquguqukayo yemoto. Ijubane lokudlulisa lingashintshwa. Ukuma okuqondile nge izinzwa ezisezingeni eliphakeme. Ubude, ububanzi nokujiya kwengilazi kungalinganiswa ngemuva kokumiswa kahle.

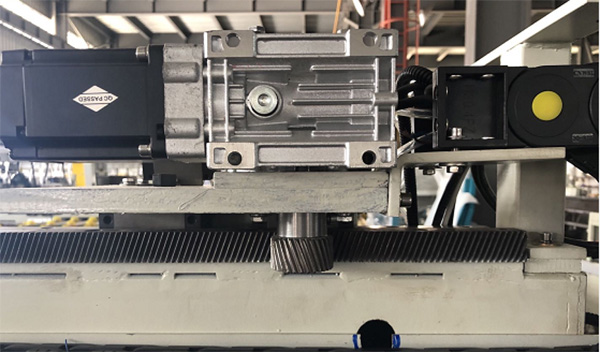

2. Ukulinganisa idivayisi

Ubukhulu bengilazi nobubanzi bengilazi bulinganiswa ngenzwa yegiya yokushayela ecacile iqhutshwa yi-servo motor. Ubukhulu bokushuba kwengilazi kulinganiswa ngokucindezelwa kwebhulokhi okuyinayiloni okucindezela ebusweni bengilazi kanye ne-encoder eqhutshwa ngamagiya. Ingcindezi isilinda kushintshwa eceleni.

3. Uhlelo lokulawula ugesi

I-ECS iqukethe isilawuli esihlelwe (PLC), isikrini sokuthinta (HMI), umshayeli we-servo, i-servo motor, isiguquli semvamisa, imoto yokuguqula imvamisa, inzwa, njll. I-PLC ilawula umshini ukuthi usebenze ngokuzenzakalela ngokuya ngobuchwepheshe bokucubungula. I-HMI iqedela umsebenzi wokusebenzisana komuntu nekhompyutha.

4. Isystem yesoftware

Uhlelo lwesoftware luqhathanisa idatha kusuka etafuleni lokulinganisa ingilazi nedatha yoku-oda, futhi ifana ngokuzenzakalela nedatha yengilazi eseduzane. Khonamanjalo, idatha yengilazi idluliselwa kwi-double edge grinder neminye imishini yokucubungula imodi noma ukukhiqizwa kwe-batch.

I-princple esebenzayo:

Ngesandla noma ngokuzenzakalela faka ishidi elilodwa lengilazi etafuleni lokulinganisa ingilazi. Ithebula lokulinganisa ingilazi lidlulisa, isikhundla futhi ulinganise ngokunembile ubukhulu bobude bengilazi, ububanzi nobukhulu. Idatha yengilazi elinganisiwe idluliselwa ohlelweni lokuphatha ukuze iqhathaniswe ukufanisa idatha ye-oda futhi idluliselwe kugraya onqenqemeni oluphindwe kabili neminye imishini yokucubungula ukucutshungulwa kwengilazi yesikhathi esizayo. Ishidi elilodwa elilandelayo lengilazi lifakwa etafuleni lokulinganisa ingilazi bese liqala umjikelezo wokusebenza olandelayo.

2. Ingilazi iqonde umugqa onqenqemeni wokucwebezelisa umshini.

Imodeli No.: SM2242GT SM2225GTS

Lo mshini wenzelwe ukupholisha imiphetho emibili yengilazi ngasikhathi sinye.

a) Ukulawula

Lo mshini wamukela ukulawula kweJapan Mitsubishi PLC kanye ne-10 ”interface interface. Isikrini sikhombisa yonke imingcele enemininingwane yengilazi. Umshini ngamunye ungalawulwa ngekhompyutha yawo noma ulawulwe yikhompyutha eyinhloko.

Ilungelo lomsebenzisi lingahlelwa njenge-opharetha / ukukhanda / umphathi, ukuvimbela iphutha elenzeka, ukuvikela umshini ekusebenzeni kabi.

b) Ukudlulisela ngokunemba okuphezulu.

Amabhande amabili wokuhambisa isikhathi aqhutshwa ama-servo motors amabili, anesici sokunemba okuphezulu, isivinini esikhulu, ukuvumelanisa okuphezulu.

c) Ukuhamba kwesigaba sokugaya okuhambayo.

Isigaba sokugaya esinyakazayo sihamba ngomugqa we-twin ball bearing guide. Ukudluliswa kwenziwa ngezikulufo zebhola, eziqhutshwa yi-servo motor, isivinini sokuhamba kweMax sesigaba sokugaya singafinyelela kumitha eyi-15 ngomzuzu. Lolu hlelo lubuye lubandakanye ukubopha kanye nokubamba uhlelo, okungaqinisekisa ukuhamba okuzinzile kwesigaba sokugaya, amandla womthelela ophansi. Lesi sakhiwo singaqinisekisa ukuzinza kwamandla abamba ingilazi enkulu ngosayizi, noma ngabe umshini usebenza isikhathi eside.

d) Njalo i-edger ephindwe kabili inesitimela esisodwa sokweseka esiphakathi nendawo, esihamba nesigaba se-grinidng esinyakazayo, esisekela ingilazi ukusuka endaweni emaphakathi ukuvikela ingilazi ekugoqeni. Ngosayizi omkhulu kakhulu ophindwe kabili, siphinde sinikeze isitimela sokwesekwa esisodwa esiphathekayo, esingabekwa ngesandla sidinga.

e) Uhlelo oluphezulu lwaphezulu nolwehla phansi lusebenzisa isakhiwo sokuhambisa ipuleti ngaphandle kwenkinga ebambekile yesistimu yemikhono yendabuko

f) Uhlelo lokubeka.

Isistimu yesikhundla sokulayisha ingilazi ifaka izingxenye ezine: ama-roller ahleliwe, isistimu yokubamba umoya ehambayo, ukuvumelanisa amabhlogo (eyodwa kwesobunxele nakwesokudla esisodwa), ama-roller aphezulu okucindezela umoya (okukodwa kwesobunxele nakwesokudla esisodwa). Ingilazi iqondaniswe kahle futhi icindezelwe ngokuqinile ngohlelo lokubeka. Lolu hlelo luqinisekisa ukugaya ukucacisa kanye nokupholisha umphumela.

g) Ukulungiswa okulula

Ukukhuphuka / ukwehla kohlelo lokulandela ngomkhondo oluphezulu kanye nama-arris aphezulu aqhutshwa ama-motors. Ingasethwa ngokuzenzakalela ngokuya ngobukhulu bengilazi ehlukile.

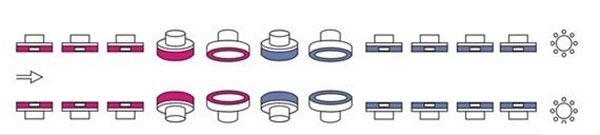

h) Uhlelo lokupholisha umoya.

Isondo lokucwebezelisa liqhutshwa ngumoya, olawulwa yi-PLC ne-valve kagesi, engaya phambili / emuva ngokuya ngendawo yengilazi. Lolu hlelo lunganxephezela ngokuzenzakalela ukugqokwa kwamasondo, lunikeze ingcindezi engaguquguquki engilazini nokuthola umphumela ofanayo wokucwebezelisa.

Isistimu yokupholisha imoto ehambayo isebenzisa uhlelo oluphakeme kakhulu lwesitimela esine-slide esilinganayo.

i) Ngaphansi nohlaka:

Zenziwe ngensimbi ejiyile eyenziwe, elashwa ngesithando somlilo efektri yethu. Ngokuqina okuhle namandla okulwa ne-torsional, amandla okulwa nokugoba.

j) Izimoto

Sebenzisa ukucacisa okuphezulu, ukudlidliza okuphansi kwe-ABB frequency frequency motor. Ijubane lama-motors lingakhuphukela ku-4300RPM ngokusebenzisa imvamisa yokuguqula, isivinini sokusebenza komshini singakhuphukela kumamitha ayi-20 / iminithi.

Uhlelo lokulawulwa kwezimoto lunomsebenzi wokuvikela we-overload / lack phase / short circuit, izingxenye ze-elekthronikhi zisebenzisa uphawu lomhlaba wonke, izinhlobo ezijwayelekile, zingatholakala kalula emakethe, ezinciphisa izindleko zokugcinwa kwamakhasimende, zikhuphule ukusebenza kahle komkhiqizo.

k) Ukuhambisa okuhamba phezulu / phansi zamukele amabhande wesikhathi.

l) Ukuthambisa

Ibhola lamawele eliphethe isikulufa esiqondile kanye nojantshi womhlahlandlela luthanjiswa ngompompo kawoyela othomathikhi.

Umshini ubuye wafaka nepompo yokuthambisa yokuhambisa ngesandla, ethambisa indawo eshelelayo.

m) Ukulungiswa kwejubane lokusebenza: Ngokusebenzisa imvamisa inverter.

n) Ithangi lamanzi, ithileyi lamanzi, ikhava yebhande yesikhathi esiphezulu / phansi, izembozo zomugqa wesitimela / isikulufa sebhola zenziwa ngensimbi engagqwali.

o) Imitha ye-Amperometer:

hlola ukusizakala kwesondo.

Imininingwane eminingi izithombe.

I-Corner cut motor yokugaya

Ukumiselela imojuli yokuxhuma engena amanzi eguquguqukayo Isibonisi esizwakalayo se-ampermeter ephezulu naphansi ye-arris motor.

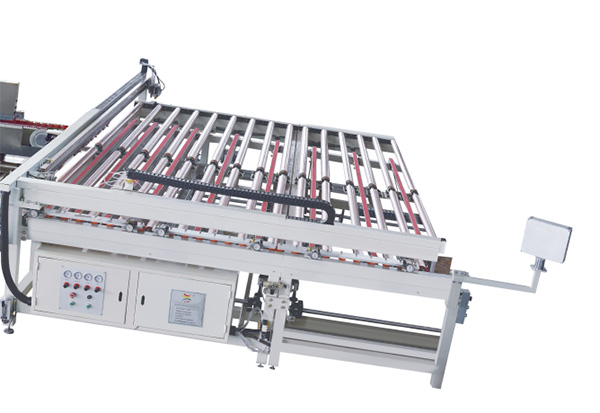

3. L- umumo Wethebula lokudlulisa. Ithebula le-roller nebhande lesikhathi.

Lo mshini wakhiwe ngohlelo lokuhambisa ama-roller nesikhathi sokudlulisa ibhande. Uhlelo lokudlulisa i-roller luqhutshwa ngamaketanga, isivinini sishaywe yi-inverter accoring kusivinini sokusetha.

Isikhathi sokudlulisa ibhande singasukuma futhi sehle phansi. Lapho ingilazi iphuma ku-edger yokuqala yokuqala, uhlelo lwebhande lesikhathi luzophakanyiswa. Ingilazi izohanjiswa ku-positon yangakwesokudla bese yehliselwa kusistimu yokudlulisa ama-roller.

Isikhathi sohlelo lokuhambisa ibhande sisebenzisa umzimba wephrofayili ye-aluminium.

Imingcele yobuchwepheshe

Ijubane lokukhiqiza

| Into | Ukujiya kwengilazi | UMax. isivinini sokusebenza | Ingilazi Qeda |

|

1 |

4 - 6 mm | 22 m / iminithi | Ukugaya okunzima |

|

2 |

8 -10 mm | 18 m / iminithi | Ukugaya okunzima |

|

3 |

12 - 15 mm | 15 m / iminithi | Ukugaya okunzima |

|

4 |

4 - 6 mm | 16 m / iminithi | Wokucwebezelisa Fine |

|

5 |

8 -10 mm | 14 m / iminithi | Wokucwebezelisa Fine |

|

6 |

12 - 15 mm | 12 m / min | Wokucwebezelisa Fine |

Ukusebenza ngokunemba:

| Into | Incazelo | Ukunemba Ibanga |

|

1 |

Ukunemba komugqa we-diagonal | ≤0.5mm / m |

|

2 |

Ngokunemba Parallel | ≤0.2mm / m |

|

3 |

Ukucaciswa kwesayizi ka-Arris | ≤0.2mm / m |

|

Into |

Ipharamitha | Ibanga |

|

1 |

UMax. usayizi wengilazi | 4200x2500 mm |

|

2 |

Ubuncane. usayizi wengilazi | 350 x 350 mm, singe edger double ngaphandle kobakaki ophakathi)400 x 400 mm (umugqa wonke) |

|

3 |

Ukujiya kwengilazi | 3 - 28 mm |

|

4 |

Ububanzi be-Arris: | 1 - 3 mm |

|

5 |

Ukugaya ukujula | 3 mm (uhlangothi olulodwa) |

|

7 |

Ijubane lokulungisa ububanzi | 1 - 15 m / iminithi |

|

8 |

Ukusebenza kwengcindezi yomoya | 0.7 MPa |

| Ukusebenza ukuphakama: | 920 - 960 mm | |

|

9 |

Qedela amandla | Cishe i-135 KW / 380V 50Hz 3P |