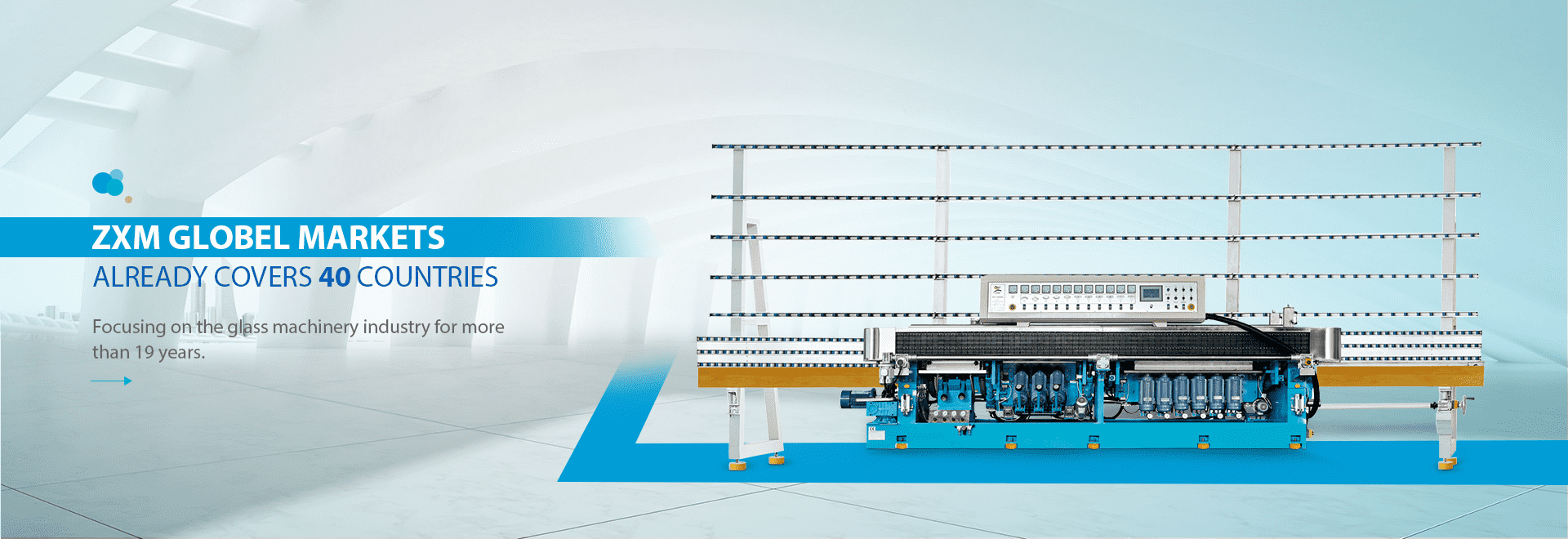

Uyemukelwa kumawebhusayithi ethu!

- Ingilazi Edging Machine

- Glass Drilling Machine

- Umshini Wokuwasha Ingilazi

- Glass Beveling Umshini

- Ingilazi ye-Sludge Dehydrator

- Ingilazi Sandblasting Machine

- Ingilazi Wave Beveling Machine

- Ingilazi Double Ukuhlela Machine

- Umshini Wokugaya we-Glass Round Edge

- Ingilazi eguqukayo engela edging Machine

- Umumo Glass Ukugoqa / Beveling Machine

-

Izinjini eziyi-10 zebhola elizenzekelayo elinomshini osindayo wokulungisa ingilazi umshini wokunciphisa

Lo mshini unama-motors ama-6 angacubungula onqenqemeni lwengilazi nolwe-front arris (0-45 degree), enezinjini ezi-2 zokuthunga ngaphambili nezimoto ezi-2 zokuthunga ngemuva. Lo mshini usebenzisa UHLELO LOKUTHUTHUKISA ISIQINISEKISO. Ifanele ingilazi encane (40mmx400mm) nengilazi esindayo (4mx4m) ukucutshungulwa. Umshini unendlela yokuvikela ingilazi yokujiya. Lapho ingilazi yokujiya okungalungile ifakwa emshinini, umshini uzoma ngokuzenzakalela. Lokhu kuvikela amabhere ekuchobozekeni. Umshini wamukela ukulawula kwe-PLC kanye ne-interface interface. Ijubane lokusebenza lingashintshwa nge-stepless regulator. Ingilazi elicutshunguliwe likhanya kakhulu futhi libushelelezi, lisondela endaweni yokuqala yengilazi. Lo mshini ubuye uboniswe ngobubanzi bokucubungula nokusebenza okulula. -

Ama-motors ayi-11 ibhola elizenzakalelayo elinomshini oguquguqukayo wengilazi ohlela imishini

Lo mshini unama-motors ayi-6 (No.1-No.6) ongacubungula onqenqemeni lwengilazi nolwe-front arris (0-60 degree), ama-motors ama-3 (No. 7-No.9) angacubungula onqenqemeni lwengilazi futhi abuye ezansi onqenqemeni, ngama-motor amabili wokuthunga kwangemuva. Yonke inqubo iphelile ngohambo olulodwa. Ukwenza i-flat edging / polishing, i-No-1-motor motors idinga ukuhlala ku-ZERO degree naku-No. 7-9 motor ingashintshwa ibe yi-45 degree ye-front arris. Ukwenza i-miter kanye ne-bottom edge, ama-No-1-motor motors angashintshwa afike ezingeni eliceliwe futhi ajike ama-motor we-No-7-No.9 abe yi-ZERO degree yokucubungula okungezansi. Lo mshini usebenzisa UHLELO LOKUTHUTHUKISA ISIQINISEKISO. Ifanele ingilazi encane (40mmx40mm) nengilazi esindayo (4mx4m) ukucubungula. -

Izinjini eziyi-15 zebhola elizenzekelayo elenza umshini wokuguqula ingilazi oguquguqukayo oguquguqukayo

Isigaba sokuqala sama-motors (No. 1-No.6) sokucubungula ingilazi engezansi nangasemaphethelweni ngaphambili (0-60 degree), ama-motors ama-2 (No. 7-No.8) we-back arris seaming nama-2 motors (No. 9-No. 10) yokuthunga ngaphambili. Cha. 11 no-No.13 motors zenzelwe ukugaya onqenqemeni oluphansi nokupholisha okokugcina lapho ama-motor No.1-No.6 wokucutshungulwa kwesigqoko sangaphambili. Amasondo amabili okugcina awokupholisha ngaphambili nangemuva. Yonke inqubo iphelile ngohambo olulodwa.

Lo mshini usebenzisa UHLELO LOKUTHUTHUKISA ISIQINISEKISO. Ifanele ingilazi encane (40mmx40mm) nengilazi esindayo (4mx4m) ukucubungula. Isakhiwo sabakaki abaphezulu singenza ama-conveyors asebenze kahle ukuze asebenze ngosayizi omncane kakhulu wengilazi engu-40mm. -

ulayini wokuhlela kabili isivinini esikhulu sengilazi yokuqedela ithebula lokudlulisa

Lo mugqa wokukhiqiza uqukethe itafula elilodwa lokulinganisa usayizi wengilazi ohlakaniphile, ama-edgers amabili netafula elilodwa lokudlulisa i-L-Shape. Itheku liyatholakala ngokuxhuma itafula lokulinganisa nohlelo lwe-ERP nohlelo lokuskena ukwenza lula isidingo sokukhiqiza esizenzakalelayo. Ithebula lokulinganisa ingilazi lisetshenziselwa ukudlulisa nokubeka ingilazi ukuthi icutshungulwe, yenza isilinganiso esinembile sobude, ububanzi nobukhulu bengilazi, futhi kudluliselwe imininingwane kusixhumi esisebenza onqenqemeni nezinye izinto zokucubungula ukuze kuqhutshekwe kwenziwe ingilazi. -

ama-edger ayisicaba ama-edgers ayisicaba agcwele okuzenzakalelayo

Le edger ephindwe kabili ingagaya / ipholishe imiphetho emibili eyingilazi yengilazi ngasikhathi sinye. Lo mshini wamukela ukulawula kwe-PLC kanye ne-interface interface.

Isigaba sokugaya esinyakazayo sihamba ngomugqa we-twin ball bearing guide. Ukudluliswa kwenziwa ngezikulufo ezihola ibhola ezihola ibhola, eziqhutshwa yimoto ngekhefu.

Ukukhuphuka / ukuwa kohlelo lokulandela ngomkhondo oluphezulu kanye nama-arris aphezulu aqhutshwa ama-motors. Ingasethwa ngokuzenzekelayo ngokuya ngokufakwa okuhlukile kwengilazi. -

9 motor ingilazi encane beveling umshini PLC ukulawula ZX261D 361D 371D

Lo mshini wenzelwe ukwenza i-bevel kuzo zombili izingilazi ezincane nengilazi enkulu. Ithrekhi elihambayo langemuva lingahanjiswa liye phezulu naphansi ngosayizi wengilazi. Ngosayizi omncane wengilazi, ithrekhi elihambayo yangemuva lingahanjiswa phezulu. Ngosayizi omkhulu wengilazi, ithrekhi elihambayo langemuva lingahanjiswa phansi, lamukela ukulawula kwe-PLC ne-interface interface. Isikrini singabonisa ukujiya kwengilazi, i-angle ye-bevel, ububanzi botho nokuphakama kwethrekhi yangemuva.

Ama-Conveyors asebenzisa uhlelo olukhulu lokuhambisa ama-roller roller, amapayipi wokubamba ingilazi anokuklama kokusebenza ingilazi encane, kuyashintsha ngemuva kokuguga. Ingilazi yesiqinisekiso sokwakhiwa ihanjiswa kahle. Ukunemba kokusebenza kuphezulu. -

11 motor manual ingilazi beveler ngejubane ledijithali ukusebenza okulula

Lo mshini wenzelwe ukukhiqiza onqenqemeni lwentsimbi, ngokugaya komphetho ongezansi. Ama-conveyors asebenzisa uhlelo oludidi oluhlanganisiwe lwe-roller chain. Ukugaya isondo kuqhutshwa ngqo ngokunemba okuphezulu kwe-ABB motor. Ijubane ukusebenza kuyinto adjustable by Isilawuli stepless. Ujantshi wangaphambili uqhutshwa yimoto ukujwayela ukujiya kwengilazi okuhlukahlukene. Ubukhulu bengilazi nesivinini sokusebenza kukhonjiswa ekufundweni kwedijithali. Lo mshini uboniswa ngokusebenza kahle okuphezulu nokunemba, ikhwalithi ezinzile, ukusebenza okulula nokugqoka okuncane.

-

umshini we-automatical chain system oguquguqukayo we-glass edging mitering machine

Lo mshini ungenza okucwebezelayo onqenqemeni oluyisicaba, ungenza futhi unqenqema lwe-miter lwe-0-45 degree. Lo mshini usebenzisa uhlelo lwe-PLC lokulawula nokuthinta iphaneli. Umshini ungasebenza ngemodi ezenzakalelayo nemodi yezandla. Ama-motor angaphambili angama-4-6 angalungisa i-engeli isuke ku-0 degree iye ku-45 degree yokupholisha umphetho ongezansi kanye ne-miter edge. -

6 motors onqenqemeni OG onqenqemeni ethandwa kakhulu ingilazi umshini

Umshini ungakhiqiza onqenqemeni oluzungezile, i-OG onqenqemeni, nomunye umphetho wephrofayili engilazini eyisicaba. I-front conveyor ingahanjiswa ngokufana ukuze ivumelane nobukhulu bengilazi obuhlukile. Amasondo amabili okuthunga ngaphambili angasusa izingilazi eziningi, ezinciphisa umsebenzi wamasondo asemiphethweni angemuva, zandise isikhathi sokuphila samasondo athinta imithambo futhi zikhulise isivinini sokusebenza. -

umugqa womshini wokubhola onembile othomathikhi nohlelo lwe-PLC ne-Servo

Lo mshini wokubhola ingilazi ungaxhunyaniswa nomshini wokuhlela kabili ukwenza umugqa ozenzakalelayo. Ingasebenza ngokuzimela futhi. -

ZX100 ingilazi imishini umshini nge laser

Lo mshini wamukela isilawuli sesikhathi sokudlulisa isikhathi nobuchwepheshe be-oyela. I-centering of hole drill ingabekwa ngendlela ye-mechanical noma i-laser. Ingilazi yokubamba umoya womoya onengcindezi eguquguqukayo. Umshini unezimo ezimbili zokusebenza: okwenziwa ngesandla nokuzenzakalelayo. Kumodi yezandla, umshini usebenza umjikelezo owodwa kuphela. Kwimodi ezenzakalelayo, umshini usebenza ngokuqhubekayo. Umshini uboniswa ngokusebenza kwawo okuphezulu, ukulimala kwengilazi ephansi nokusebenza okulula. -

chain system othomathikhi ingilazi flat onqenqemeni wokucwebezelisa umshini puenmatic

Lo mshini usebenzisa uhlelo lwe-PLC lokulawula nokuthinta iphaneli. Isebenza okupholisha onqenqemeni oluphambili, uhlelo lokupholisha lomoya lwenza umshini ubenobungane bokusebenza, ukuphela kwengilazi kuhle kakhulu. Umshini ungasebenza ngemodi ezenzakalelayo nemodi yezandla. I-Conveyor use chain transmitter system, isivinini sokusebenza siyashintshwa ngokusebenzisa umlawuli wejubane.